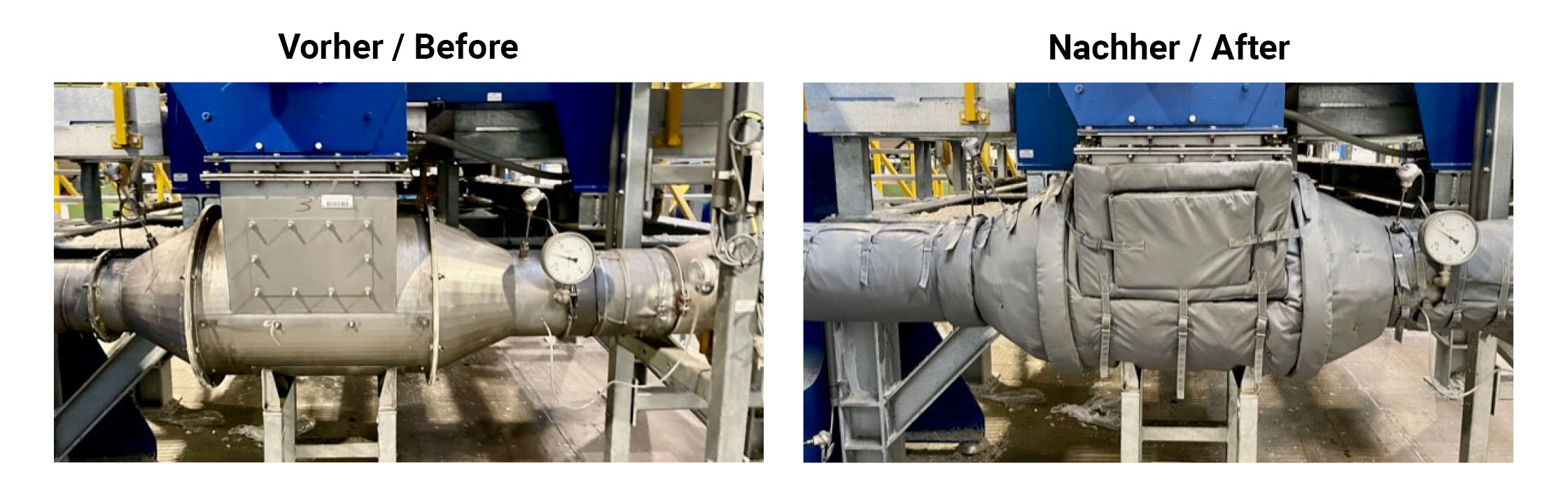

ISOWEMA® Insulation Cover

Insulation covers for heated zones in plastics processing machines

Reduce your energy consumption and therefore energy costs!

Reduce CO2 emissions!

Application areas:

ISOWEMA® - insulation covers can be individually manufactured for any heating zones irrespective of machine type. The electrical connection area is taken into account, as are the sensor inputs.

Setup:

Mechanically hardened glassfibre is sewn into an abrasionresistant

glass fabric. Both materials have a permanent

temperature resistance of max. 500 °C (also available for

higher temperature ranges as special version). The outside

of the insulation consists of a highly wear-resistant

material whose surface repels dirt and excess injected

plastic material. Thanks to the multi-layer construction in

high temperature-resistant insulation textiles, the surface

temperature and the energy losses around the heating

zones can be considerably reduced. The insulation thickness

is normally 25 mm, variations are also available.

Closure takes place using belts and a buckle. All materials

used for the manufacture of ISOWEMA® - insulation

covers are non-flammable.

Benefits:

- Reduction of machine heating energy consumption by 20 to 40 %

- Extension of heater unit service life through reduction of switching cycles

- Increase in working safety due to reduction of surface contact temperatures by 60 - 70 %

- Reduces injury hazards caused by burns

- Can be retrofitted at any time - rapid installation and dismantling

- Long service life of insulation thanks to the use of high temperature-resistant, abrasion-resistant materials

- Physiologically harmless insulation materials

- ISOWEMA®- insulation units usually have a payback time of less than 1 year

- Reduction of heating time

- Optimisation of internal climate in production halls

- Individual, customer-based production

- Uniform temperature profile at machine cylinder

- Manufacture of insulation units on the basis of 3-D data (Step/IGES formats) possible

- Measurement-taking on site possible

- Insulation units can be fitted by our staff if required

- Can also be used on extruder cylinders in connection with the ECOWEMA® - valve system