Online configurator VIKO®

Configure your individual heater with VIKO®

DH 400 Nozzle Heater Band, Mica insulated, Stainless steel Housing

Application:

Heating of nozzles on injection molding machines

Various applications possible

Heating of pipelines

Construction:

Heating element wire in special MICANITE insulation, stainless steel housing

Technical features:

Long durabilityEasy to install

Fully sealed housing against plastic penetration

Available with inbuilt thermocouple

Available with different cable lengths and lead exits

Technical specifications:

Housing material: stainless steel

Insulation material: Mica

Execution: Fully sealed housing against plastic penetration

Operating temperature: max. 350°C

Heating capacity: max. 6 W/cm²

Supply voltage: 230 or 400 V (other available)

High-voltage strength: 1500 V-AC

Insulation resistance: 1 MOhm (at 500 V-DC)Inbuilt thermocouple: available (standard: FeCuNi, type J, grounded; optional: not grounded)

Internal diameter (d): 25-110 mm

Width (b): 20, 25, 30, 35, 40, 45, 50, 60 mm

Cable length: 300 mm, 500 mm, 1000 mm, 1500 mm, 2000 mm, 2500 mm, 3000 mm, 3500 mm,... (other available)

Type of cable: 3 x 0,75 mm² heat resistant nickel wire, with metal braided sleeving

Protection class: IP40

Tensioning screws: M5x20 mm, with threaded bolts

Terminal cap: stable stainless steel versions in 5 variants, type 1 to type 5

Compliance: CE

Please scroll down to find our stock executions. These can be ordered immediately in this shop. Orders received by 10:00 a.m. will be shipped the same day via UPS!

Price on request

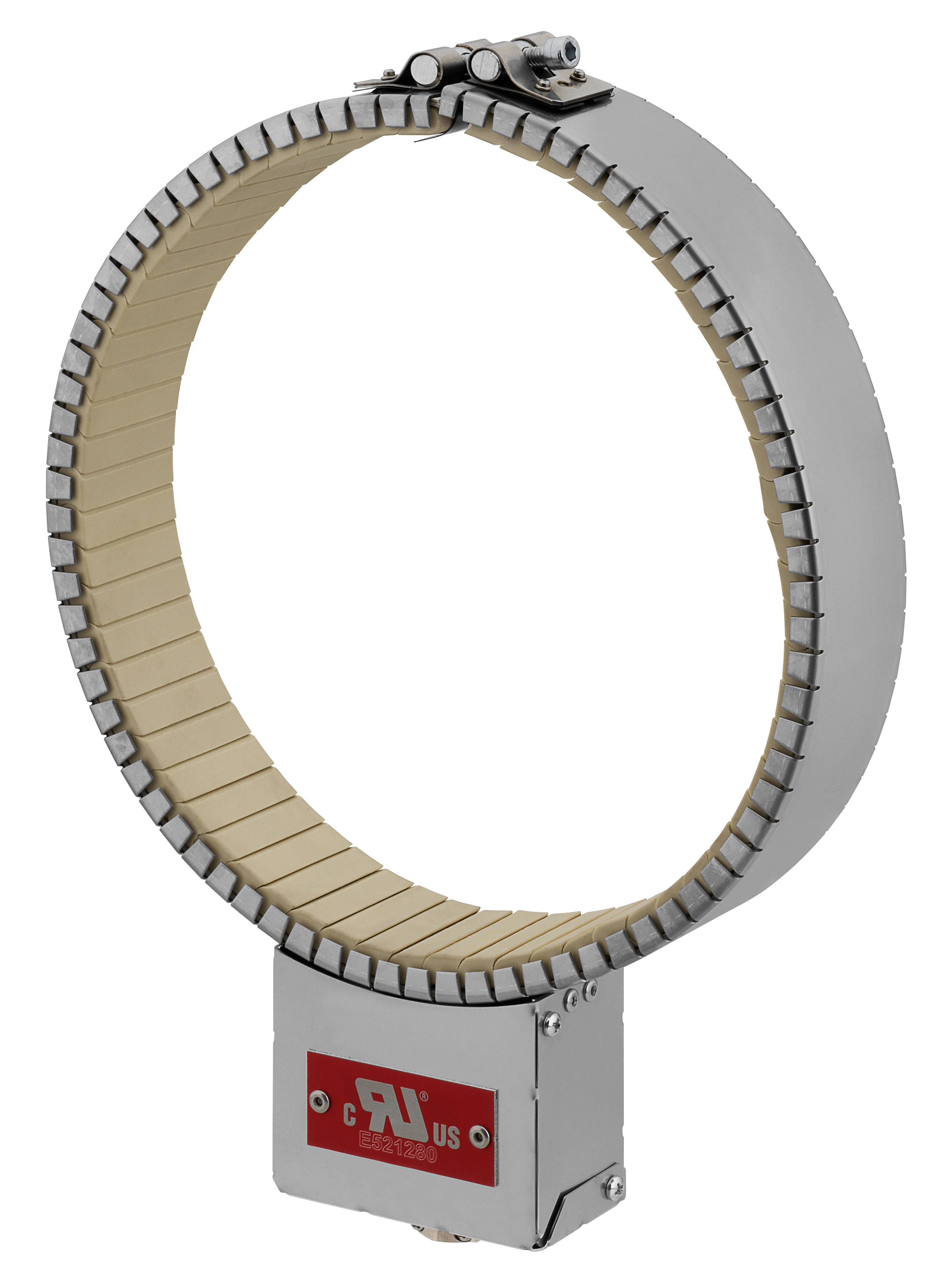

KH 210 Ring Heater, Ceramic-insulated

Application areas: Heating of cylindrical tools, flanges, plastification cylinders

and for other industrial heating applications. Construction: Heating conductor coils fitted in temperature-shock resistant

special ceramic stones. Strap retainer in 0.8 mm thick

aluminised sheet steel with compensation filler (stainless

steel strap retainer on request). Implementation types: Spreadable version with screw tab closure (in case of

larger diameters for compensating thermal expansion with

compression springs). With 2 mm compensation filler for

reduction of mechanical loading in ceramic stones (fracture

hazard!) when tightening down heater band.

Also available as half-shells or in segmental construction

in addition to mandrel heating for internal heating of

moulds or rollers. Can be supplied with bores, thermal brackets and apertures

as far as technically possible. Electrical power supply via contact fittings (plug) up to

16 A/250 V, cable fittings with ceramic terminal or permanently

fixed connecting cable.

A UL / CSA-certified execution is also available.

Technical specification: Material heating element: heater conductor coils

surrounded in ceramics

Material strap retainer:

aluminised sheet steel 0,8 mm

(stainless steel on request)

Voltage:

in acc. w. specification

Heating capacity:

max. 7 W/cm²Temperature max.:

600 °C

Wall thickness:

12 mm, incl. strap retainer and

compensation filler

Ø min.:

60 mm

Width: 18 mm, increasing in 15 mm

stages 33, 48, 63, 78, 93, 108 mm

etc. to 633 mm

Price on request

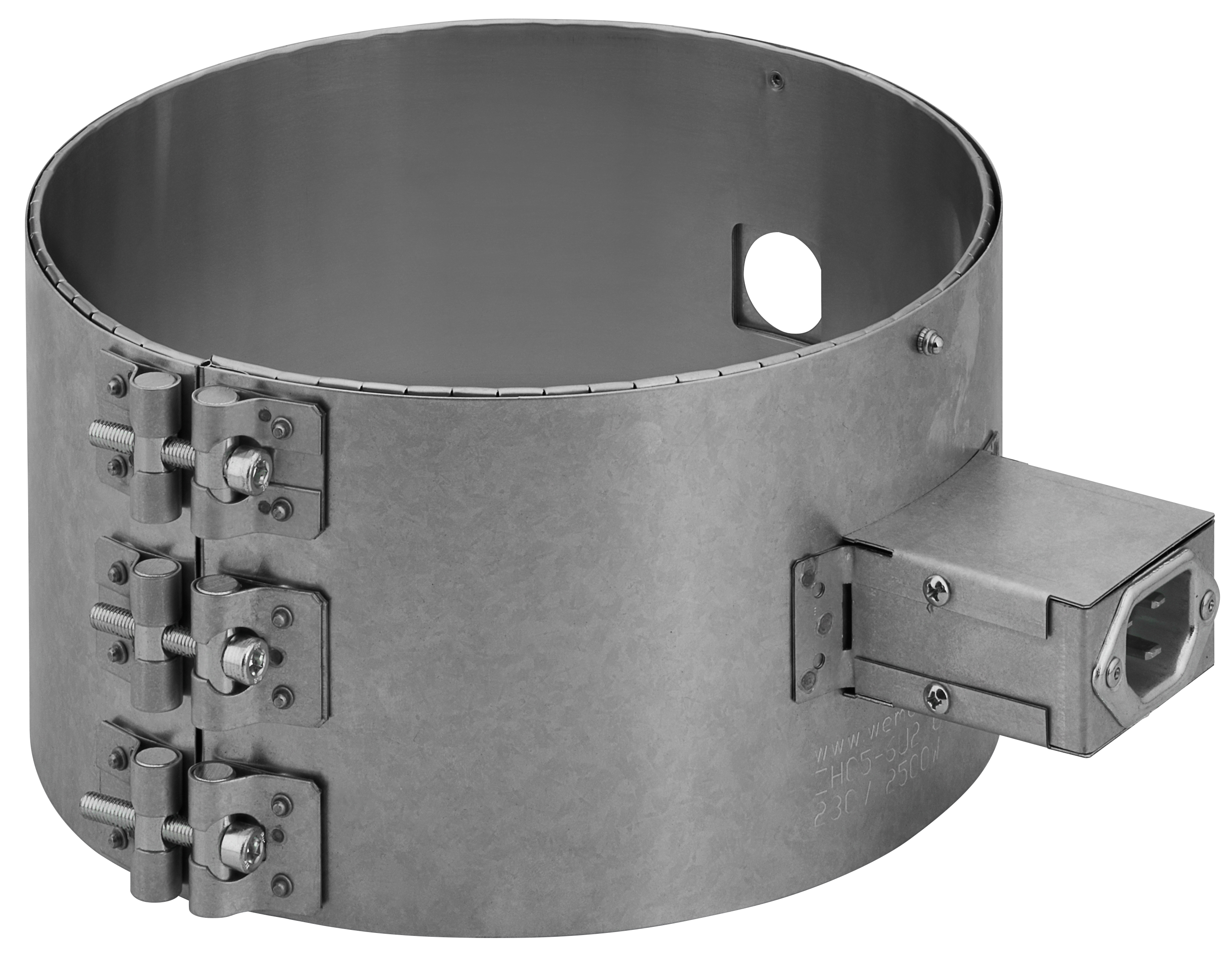

ZH 205 Band Heaters, Micanite-insulated

Application areas:Heating of cylindrical tools, flanges, plastification cylinders and for other industrial heating applications.Construction:Heating element wire in special MICANITE insulation, packed in sheet steel, with fixing strap in aluminised sheet steel (stainless steel on request).

Implementation types:

Spreadable version with screw tab closure. Half shells or segments can be supplied. Can be supplied with bores, thermal brackets and apertures as far as technically possible.

• Electrical power supply via contact fittings (plug) up to 16 A/250 V, cable fittings with ceramic terminal or permanently fixed connecting cable.

• Can also be supplied with brass heat-conducting plates.Technical specification:

Material heating element: 0,3 mm sheet steel, micanite insulation Material strap retainer: aluminised sheet steel 0,8 mm (stainless steel on request) Voltage: in acc. w. specification Heating capacity: max. 3,5 W/cm²Temperature max.: 300 °C Wall thickness: ~4 mm Ø min.: 55 mm Width: 20 – 400 mm

Price on request

BK 225 Flat Heater, Micanite-insulated

Application areas: Heating of moulds, tools and melt flow channels. Construction: Heating element wire in special MICANITE insulation,

packed in 0,3 mm sheet steel, with stainless steel guide plate (5 mm thick). Implementation types: Drill holes can be provided for fixing the heater unit to

your specifications. Can be supplied with guide bores, thermal brackets and

apertures as far as technically possible.Electrical power supply via contact fittings (plug) up to 16

A/250 V, cable fittings with ceramic terminal or permanently

fixed connecting cable.Can also be supplied with brass heat-conducting plates

(2 mm thick).Technical specification: Material heating element: sheet steel, nickel-plated

micanite insulation Material guide plate: 5 mm stainless steelVoltage: in acc. w. specification Heating capacity: max. 3,5 W/cm2 Temperature max.: 300 °C Wall thickness: 3 mm (without guide plate)

8 mm/11 mm (with guide plate)

(additional 2 mm MS heat-conducting

plate if necessary)

Price on request

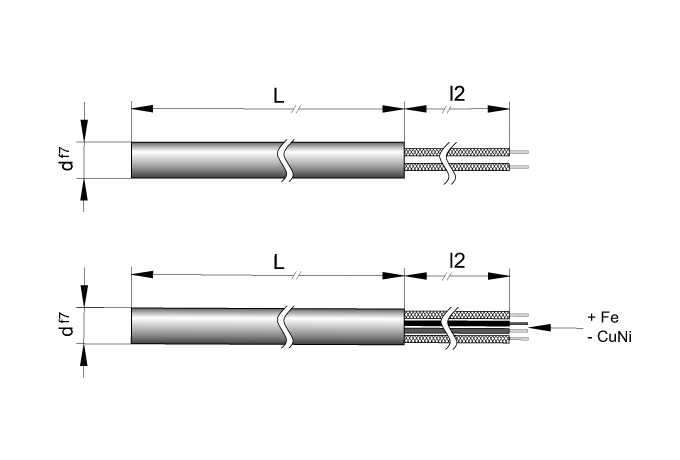

S5101 High-duty cartridge heater, metric

€153.00*

Acc. to DIN VDE 0721

With/without thermocouple FeCuNi type L

Variants from €0.00*

KH 214 Heating-cooling Band, Special Ceramic, for intensive Air Cooling

Application areas:

Heating and intensive cooling of extruder cylinders. Intensive cylinder cooling enables a considerable reduction

of the melt temperature whereby material degradation

due to temperatures being too high is avoided, melt

stiffness at the tool outlet is increased and the cooling

requirements for downstream equipment can be reduced.

This makes higher throughput performances and better

product qualities possible.

Complete, available with housing casing as heating-cooling combination HK 214, HK 216 or HK 218.Construction/version types: Heating conductor coils fitted in special ceramic stones

with temperature-resistant braid connection. Cooling fins formed on the rear for increasing the heat

exchange surface which the cooling air flows past. This

results in a 2.5-fold increase of cooling surface related

to the stone bearing surface on the cylinder. The contact surface of the stone to the cylinder is

shaped so that two contact lines for improved heat

transmission resultat any cylinder diameter. The ceramic stones consist of a special oxide ceramic

with a high thermal conductivity of 16-28 W/mK

(standard ceramic heater band: 2-3 W/mK) therefore

enable a considerably higher heat dissipation than

conventional versions. A completely flexible heater band can be produced

using the concave and convex-shaped end surfaces

of the special ceramic stones, and this can be simply

placed around the cylinder and is therefore extremely

quick to fit. Fixing is made using two stainless steel tensioning

ropes with clamping screw and compression springs.

The system enables high clamping forces, and therefore

guarantees a permanently positive contact, and

therefore ensures optimum heat transfer.The special ceramic stones have an extremely high

fracture strength, which ensures a long heater band

service life. This makes frequent assembly and disassembly

possible without problems. The special ceramic heater bands are extremely suitable

for use under high cylinder temperatures (e.g. during

the processing of fluorine polymers with a processing

temperature of more than 400 °C). Oxidisation cannot occur due to the complete lack of

additional cooling sheets (radiators) made of brass or

copper. If the heater band width is 48 or 63 mm, centrally located

sensor bores are possible. Considerably lower energy consumption than in systems

in which the heating resistor is pressed or cast in

aluminium. Simple, modular setup enables short delivery times.UL / CSA-certified execution availableTechnical specification: Voltage: in acc. w. specification Heating capacity: max. 7 W/cm²Height: 21 mm, incl. cooling fin Available widths: 30 mm, 48 mm, 63 mm Diameter: from 60 mm

Price on request

KE 300 Flexible Aluminium Cooling Element, for Intensive Air Cooling

In order to intensify the cooling effect in the case of aircooled

extruder cylinders, additional elements in the

form of cast aluminium half shells with cooling fins are

often fitted to the free cylinder surfaces between the

heater bands. These elements increase the surface area which achieves

better heat transfer between the cylinder surface and the

cooling air. Whereas high costs for the casting mould and the additionally

necessary mechanical processing for fitting to the

internal surfaces and attaching the tensioning devices

occur for the cast aluminium cooling elements, this is not

the case for the KE 300 flexible cooling element. This system is modular and consists of a large number

of individual cooling elements with cooling fins corrugated

on both sides at a height of 28 mm.

The elements are made into a row of flexible belts

using two tensioning ropes and can be produced infinitely

variably for all cylinder diameters. Available widths: 34 mm, 47 mm, 60 mm. The flexible aluminium cooling element is supplied ready

for assembly with a spring screw connection which

compensates for thermal expansion and guarantees

even pressure against the cylinder surface thanks to

the tensioning ropes. A sensor bore of diameter 17 mm can be made in the

centre. In comparison to a cast aluminium cooling element,

this solution actually has an improved cooling perfor-

mance in many cases because the material used has

a higher thermal conductivity, and because the gaps

between the individual cooling elements and the corrugated

fin surface offers a larger heat exchange surface

and a more intensive mixing of the cooling air. For application cases in which particularly high cooling

performance is required, we recommend combining

the flexible KE 300 cooling element with the ribbed special ceramic heating-cooling bands KH 214

Price on request