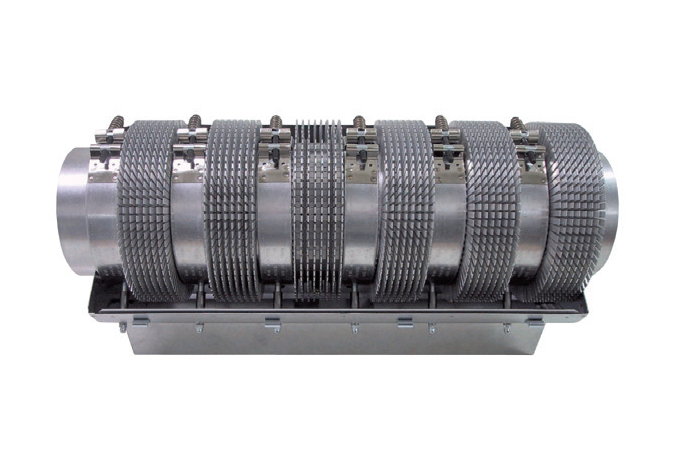

KE 300 Flexible Aluminium Cooling Element, for Intensive Air Cooling

2 - 3 weeks

In order to intensify the cooling effect in the case of aircooled extruder cylinders, additional elements in the form of cast aluminium half shells with cooling fins are often fitted to the free cylinder surfaces between the heater bands.

These elements increase the surface area which achieves

better heat transfer between the cylinder surface and the

cooling air.

Whereas high costs for the casting mould and the additionally

necessary mechanical processing for fitting to the

internal surfaces and attaching the tensioning devices

occur for the cast aluminium cooling elements, this is not

the case for the KE 300 flexible cooling element.

- This system is modular and consists of a large number of individual cooling elements with cooling fins corrugated on both sides at a height of 28 mm. The elements are made into a row of flexible belts using two tensioning ropes and can be produced infinitely variably for all cylinder diameters.

- Available widths: 34 mm, 47 mm, 60 mm.

- The flexible aluminium cooling element is supplied ready for assembly with a spring screw connection which compensates for thermal expansion and guarantees even pressure against the cylinder surface thanks to the tensioning ropes.

- A sensor bore of diameter 17 mm can be made in the centre.

- In comparison to a cast aluminium cooling element, this solution actually has an improved cooling perfor- mance in many cases because the material used has a higher thermal conductivity, and because the gaps between the individual cooling elements and the corrugated fin surface offers a larger heat exchange surface and a more intensive mixing of the cooling air.

- For application cases in which particularly high cooling performance is required, we recommend combining the flexible KE 300 cooling element with the ribbed special ceramic heating-cooling bands KH 214