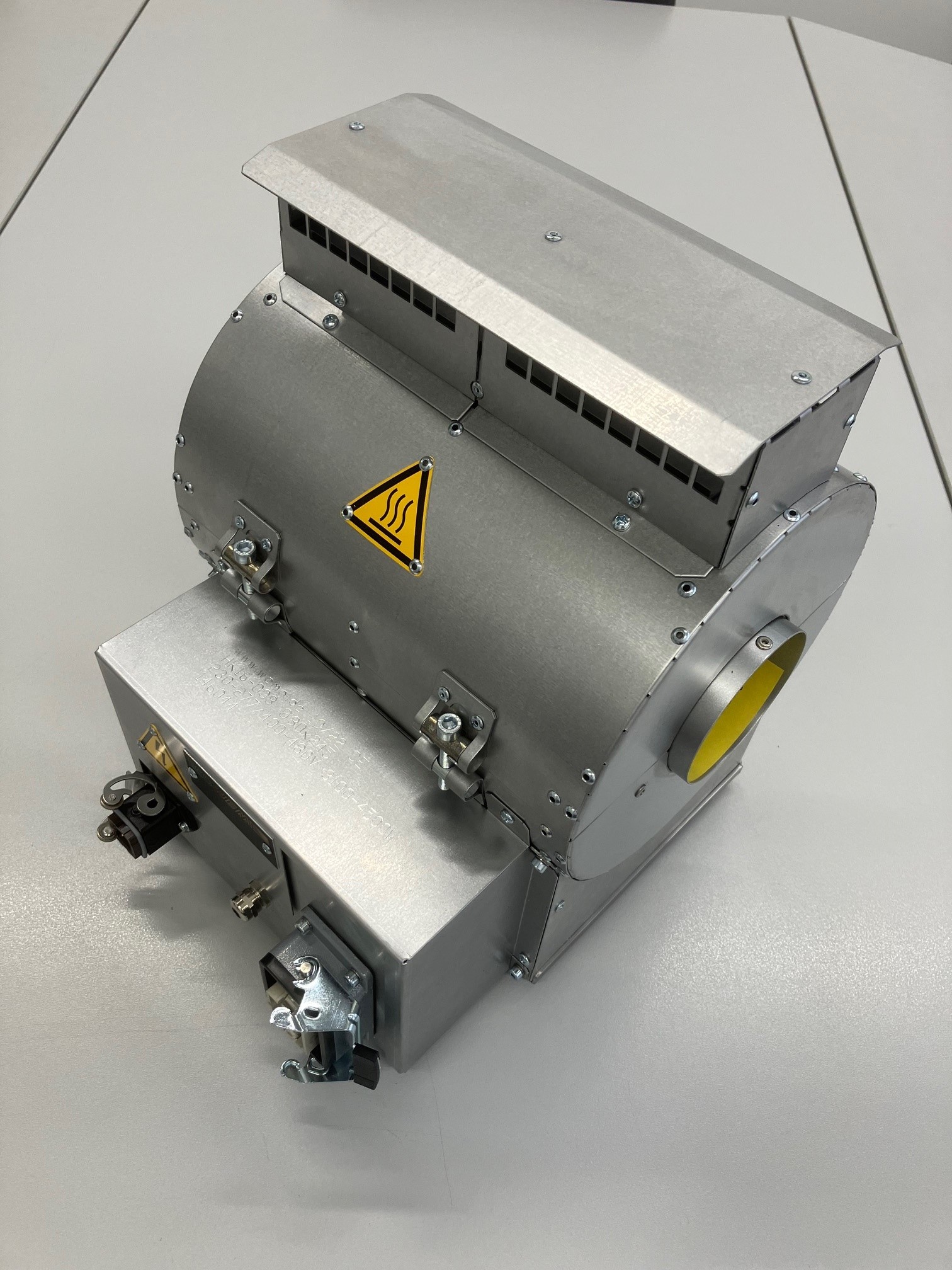

HK 213 Heating-cooling Assembly with integrated Fan, for Standard Air Cooling

Application areas:

Heating/cooling of extruder or injection moulding

cylinders

Construction/version types:

Narrow ceramic heater bands KH 210 (however WITHOUT insulating filler) of widths 33 mm, 48

mm, 63 mm and 78 mm (widths above 78 mm possible

in special cases) are fitted at regular intervals in the bottom

half of a housing casing using fixing bolts.

A compact fan in addition to specially-shaped air deflectors for distribution of the cooling air in the axial and tangential directions are also integrated in the bottom half of the housing casing.

The individual design of these air deflectors ensures the best-possible even circumfluent flow of the cylinder, and therefore counteracts any undesirable bending of the cylinder and corresponding wear.

The spacious electrical connection chamber, which stands out due to its optimum accessibility, is located on the side of the fan housing.

The individual heater bands have been electrically connected at the works.

An electrical supply cable of a defined length can be connected at the works if required.

The air outlet opening is implemented as standard in the upper part of the housing casing with air slots.

Additional air deflectors can be fitted to the air outlet opening as an option.

Sensor bores and apertures will be taken into account as far as technically possible.

The completely removable housing cover and the spreadable ceramic heater bands ensure ease of installation.

A UL / CSA certified version is also available.

A compact fan in addition to specially-shaped air deflectors for distribution of the cooling air in the axial and tangential directions are also integrated in the bottom half of the housing casing.

The individual design of these air deflectors ensures the best-possible even circumfluent flow of the cylinder, and therefore counteracts any undesirable bending of the cylinder and corresponding wear.

The spacious electrical connection chamber, which stands out due to its optimum accessibility, is located on the side of the fan housing.

The individual heater bands have been electrically connected at the works.

An electrical supply cable of a defined length can be connected at the works if required.

The air outlet opening is implemented as standard in the upper part of the housing casing with air slots.

Additional air deflectors can be fitted to the air outlet opening as an option.

Sensor bores and apertures will be taken into account as far as technically possible.

The completely removable housing cover and the spreadable ceramic heater bands ensure ease of installation.

A UL / CSA certified version is also available.

Technical specification:

- Material housing: 0,8 mm aluminised sheet steel (stainless steel on request)

- Voltage / tie-in: in acc. w. specification

- Heating capacity: max. 7 W/cm², related to the heater bands

- Temperature max.: 300 °C (special version to 500 °C)

- Diameter: from 80 mm

- Width: from 240 mm

- Circular plate height: 36,5 mm (with bolted heater bands fixing)

- Assembly of cooling element KE 300 possible at suitable spacing of heater bands

Accessories:

An ideal supplement for amplifying the cooling capacity

is provided by the flexible aluminium cooling elements KE 300, which can be mounted on

the free cylinder surfaces between the heater bands.

ECOWEMA®:

In order to reduce the energy consumption and the

thermal dissipation, insulation can be integrated in the

housing casing depending on the cylinder diameter.

Alternatively, the flexible ISOWEMA® insulation can be used.

In order to prevent convection heat loss, the ECOWEMA® flap system can be

fitted at a „12 o‘clock“ fitting position.