Application areas:

Heating/cooling of extruder or injection moulding cylinders with increased cooling requirementsConstruction/version types:

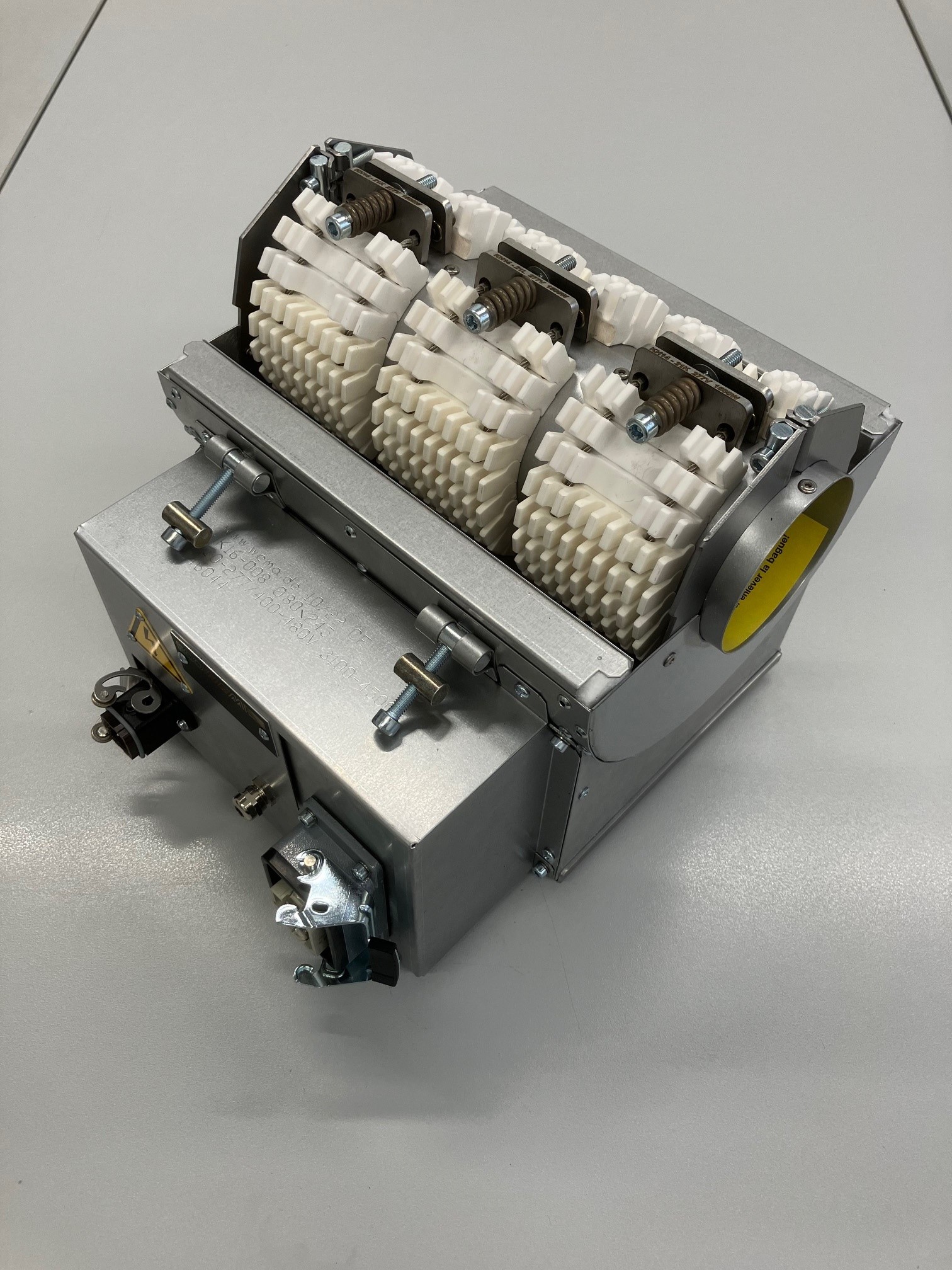

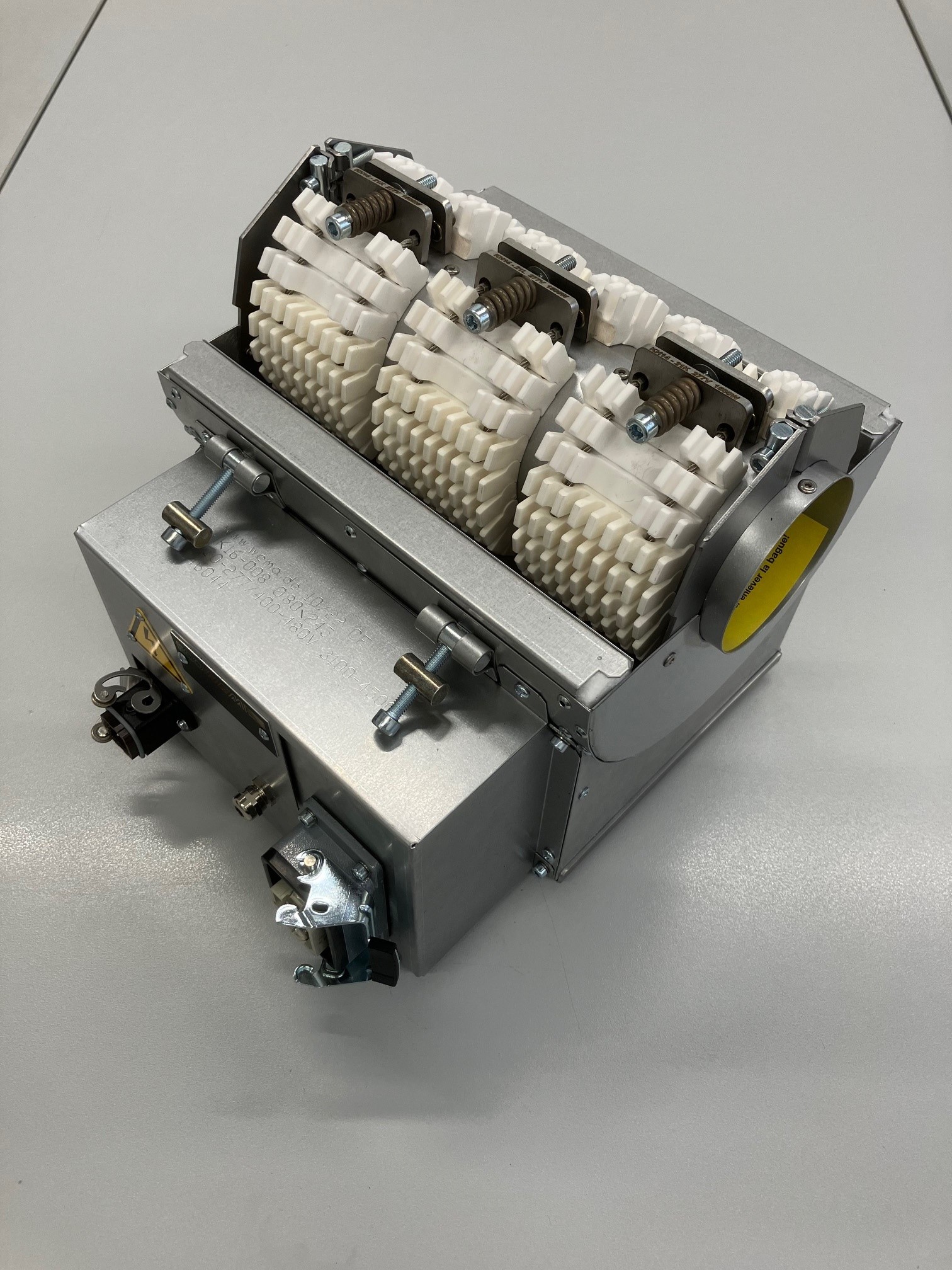

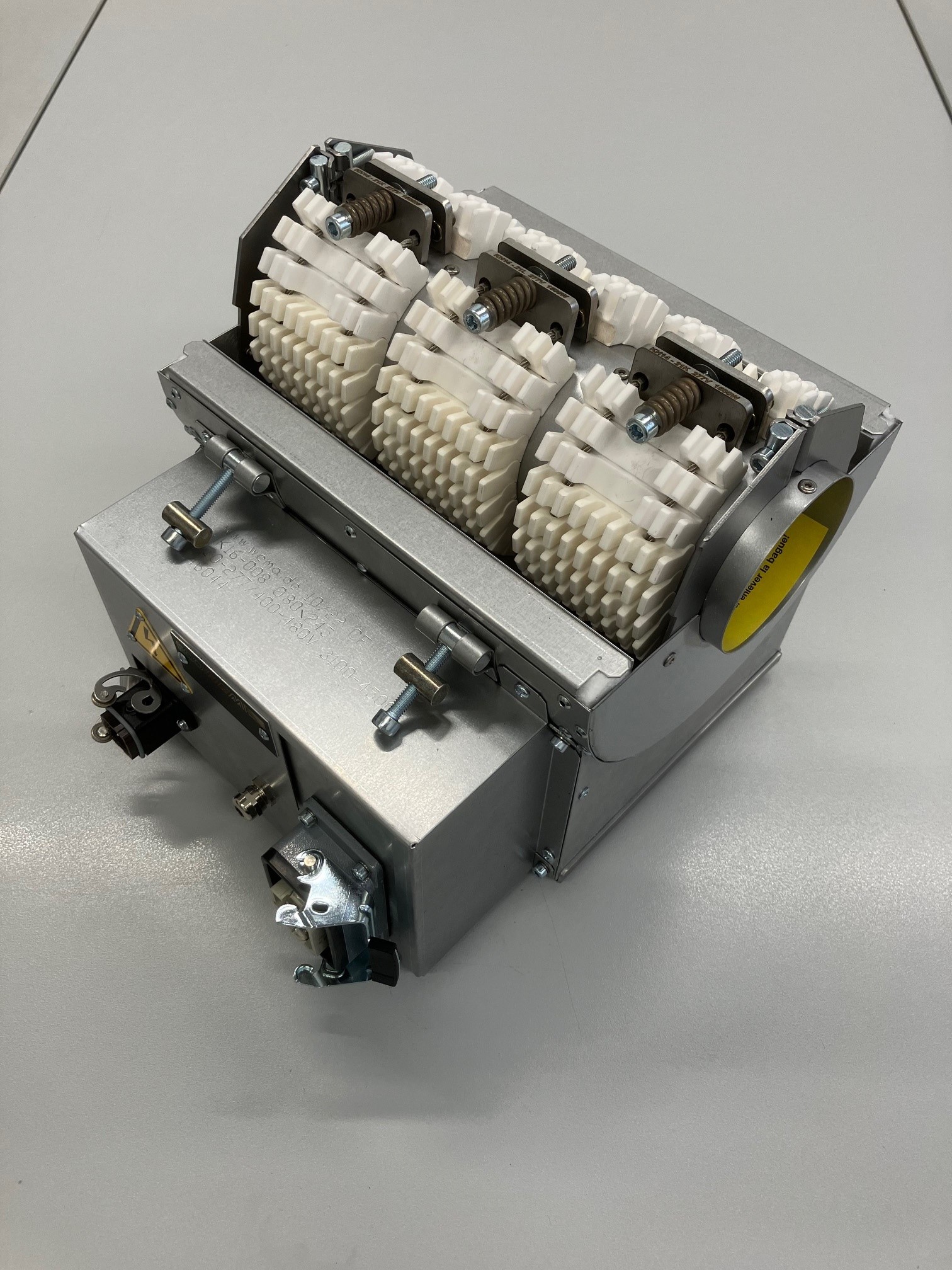

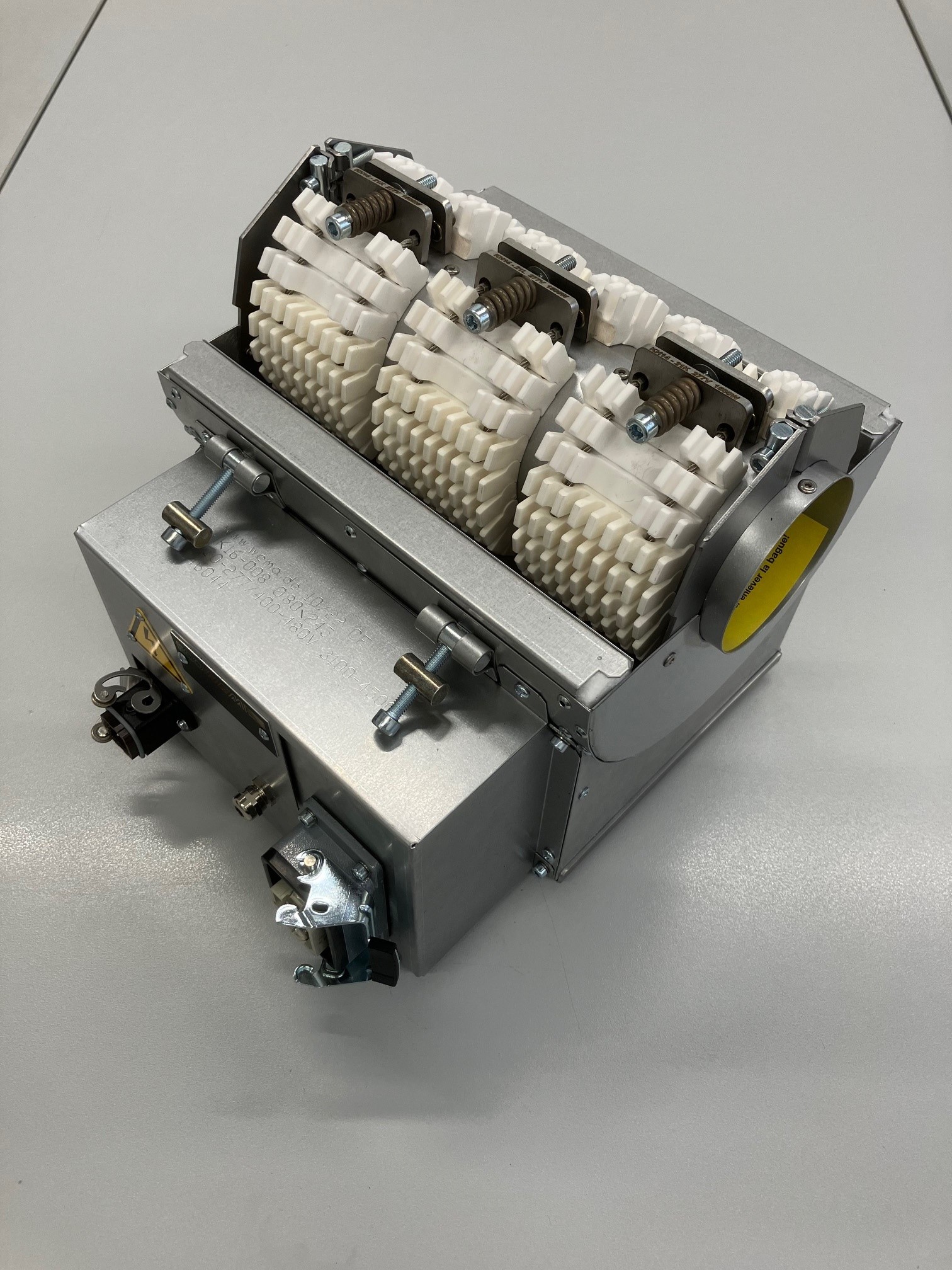

Special ceramic heating-cooling bands of type KH 214 in widths of 30 mm, 48 mm and 63 mm are mounted directly on the cylinder at regular intervals.A fixing template supplied makes alignment of the heater bands in the corresponding cylinder zone much easier.

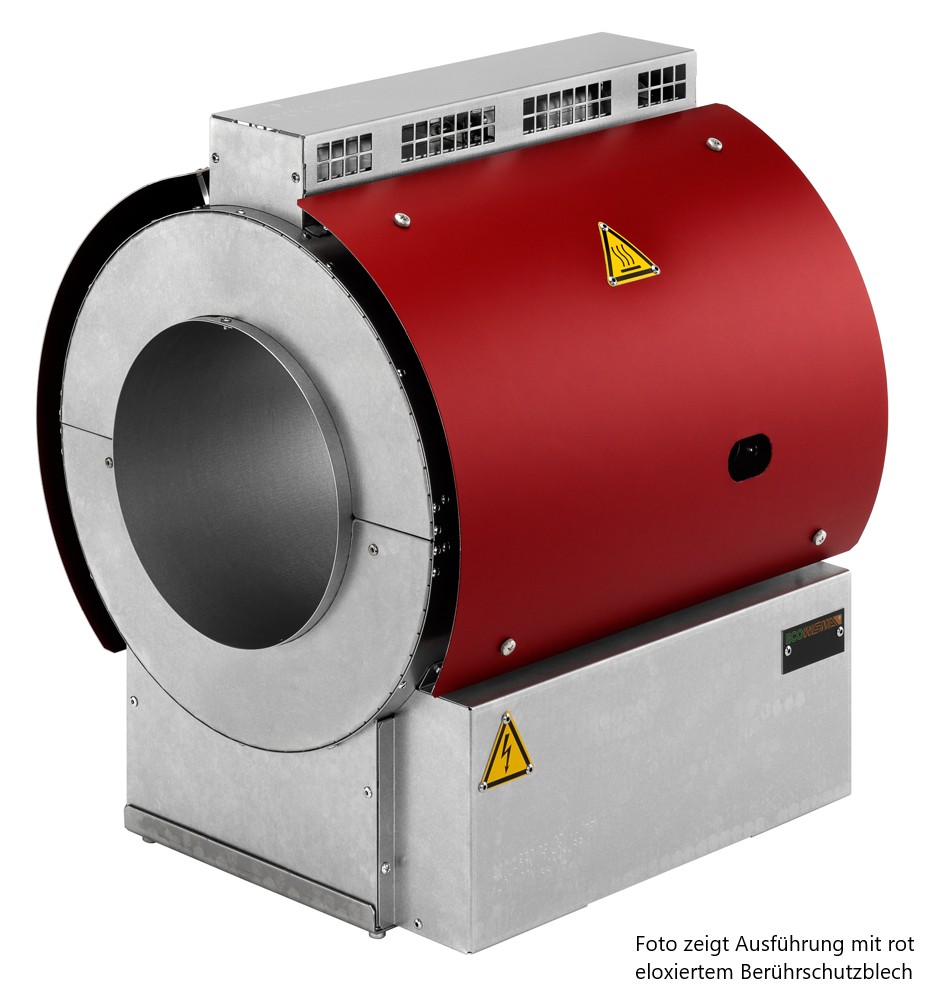

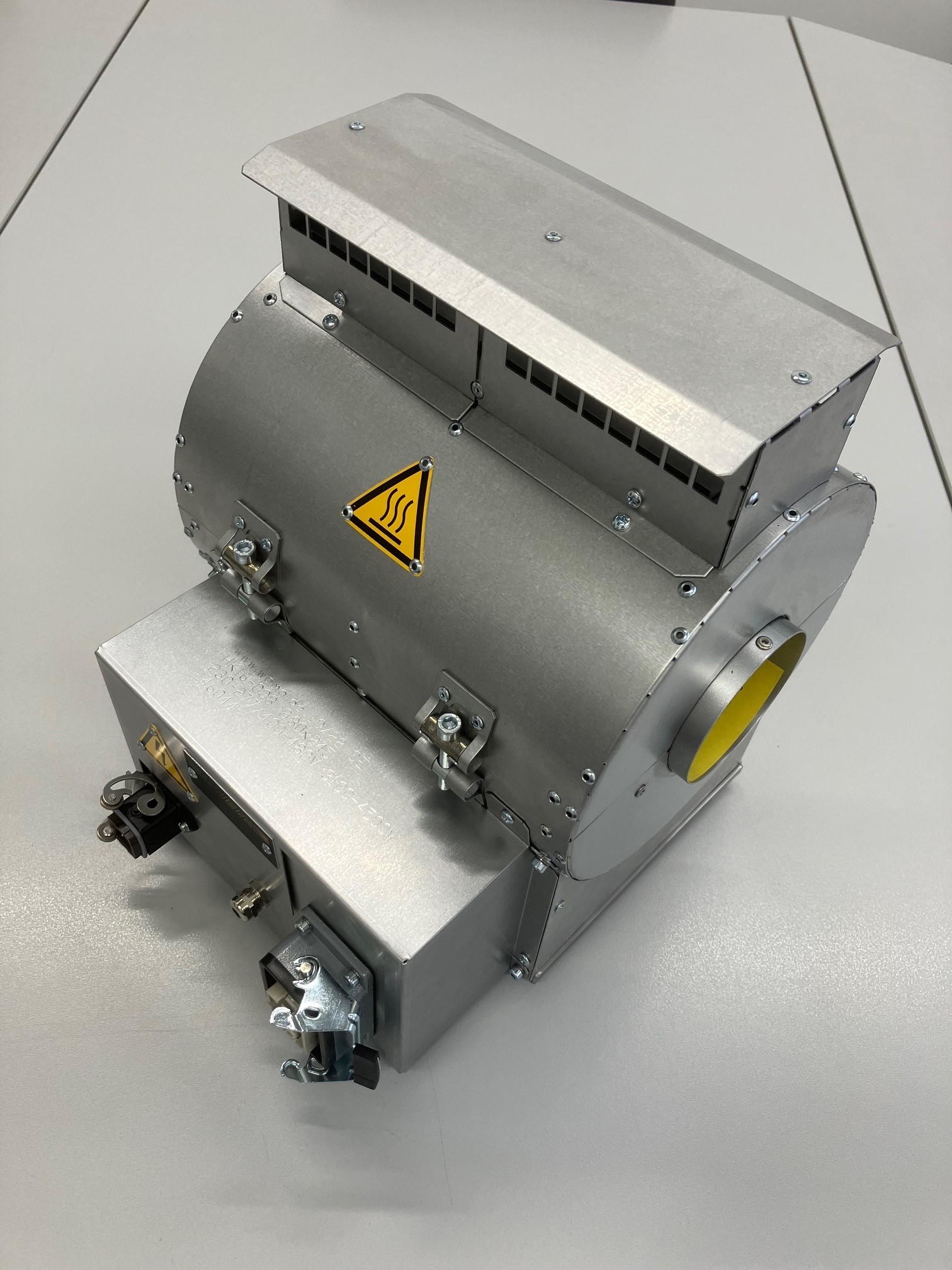

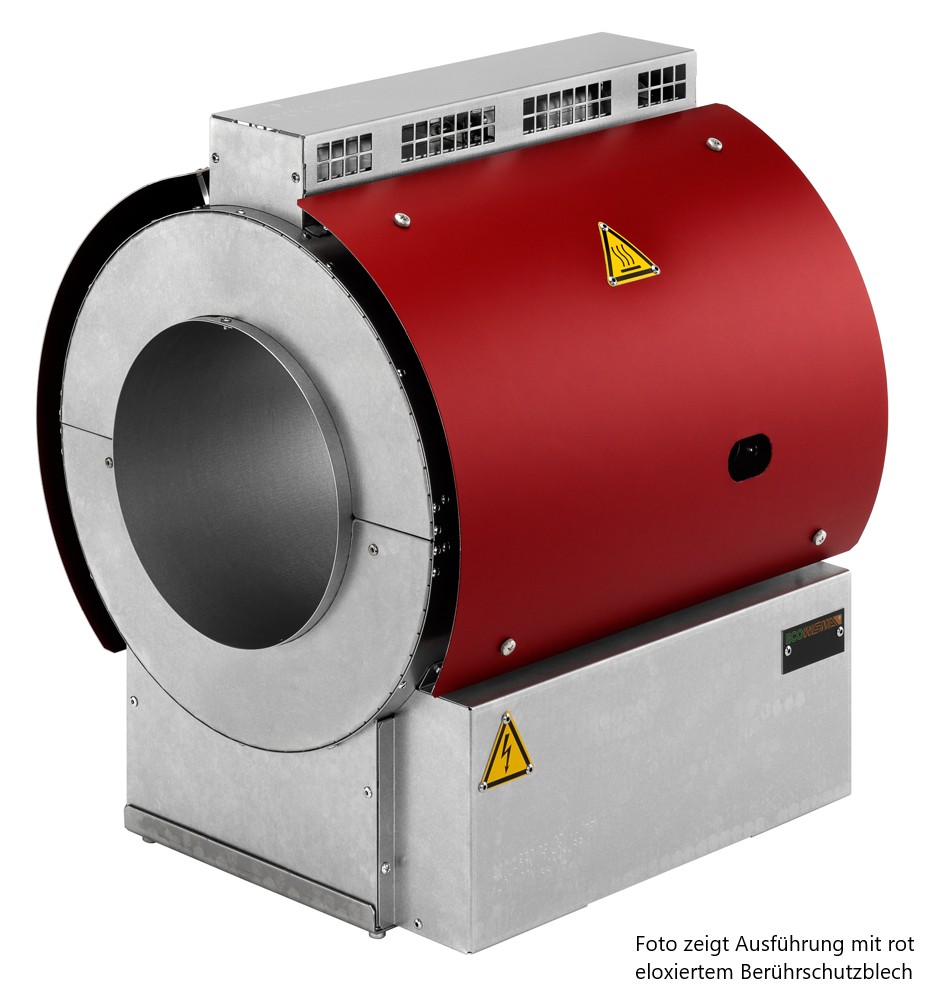

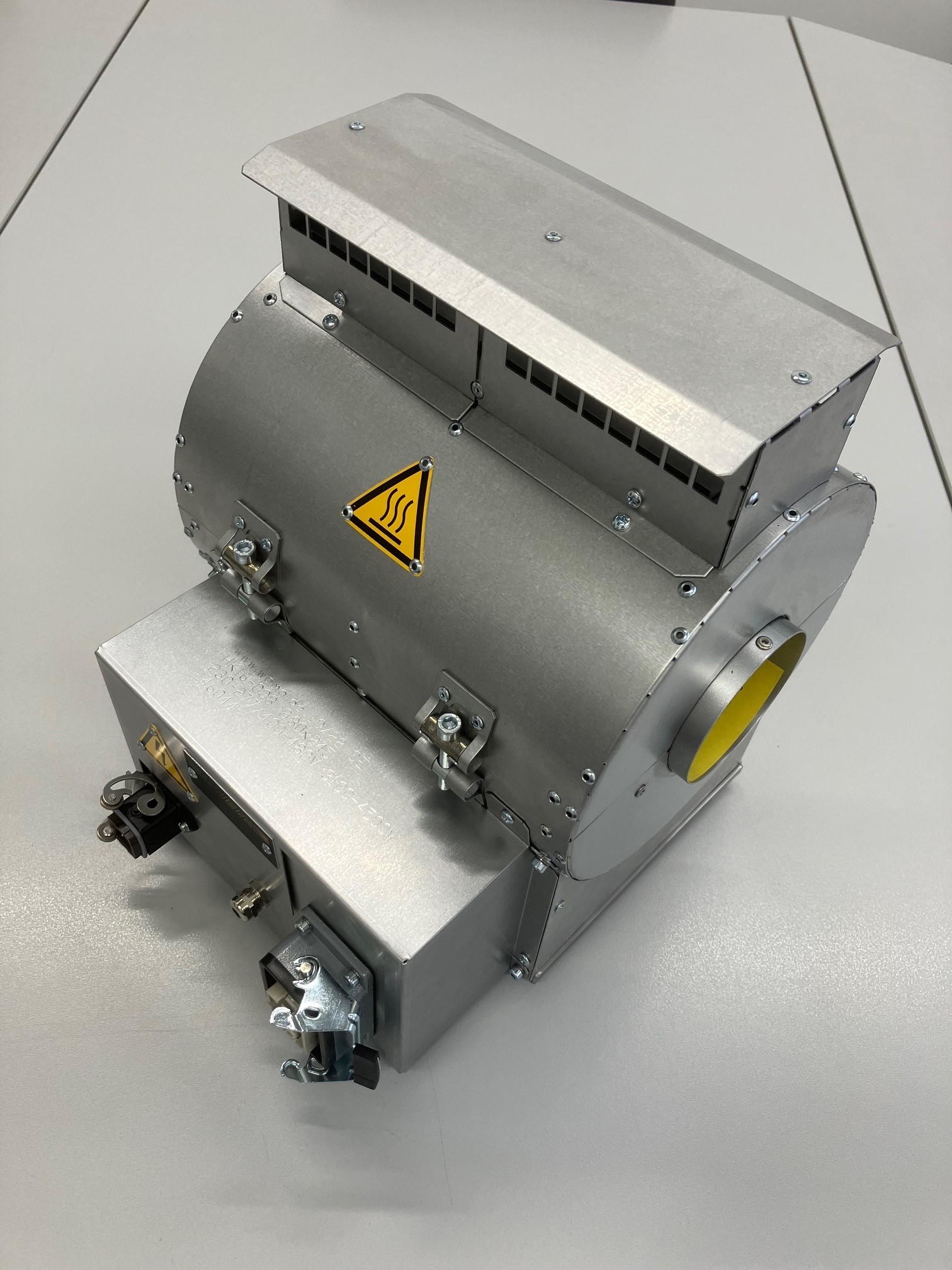

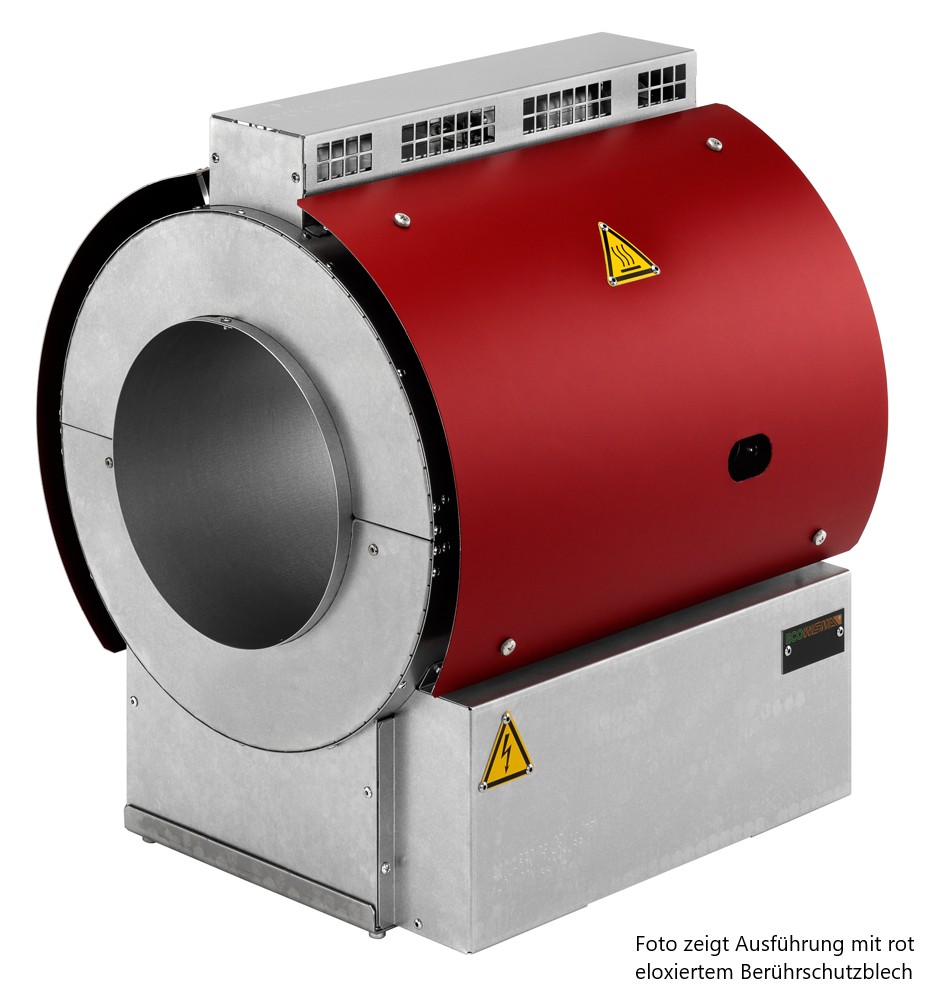

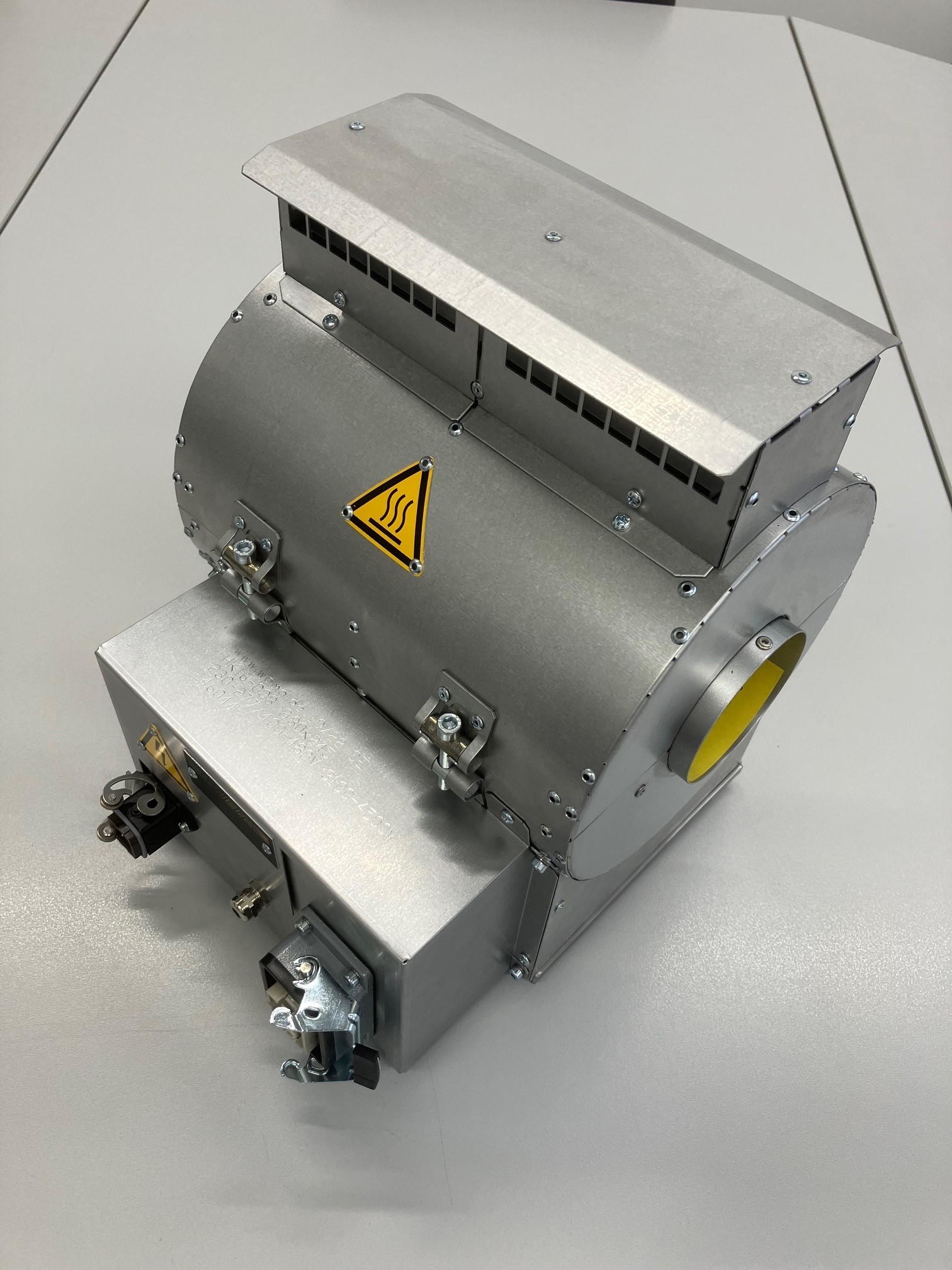

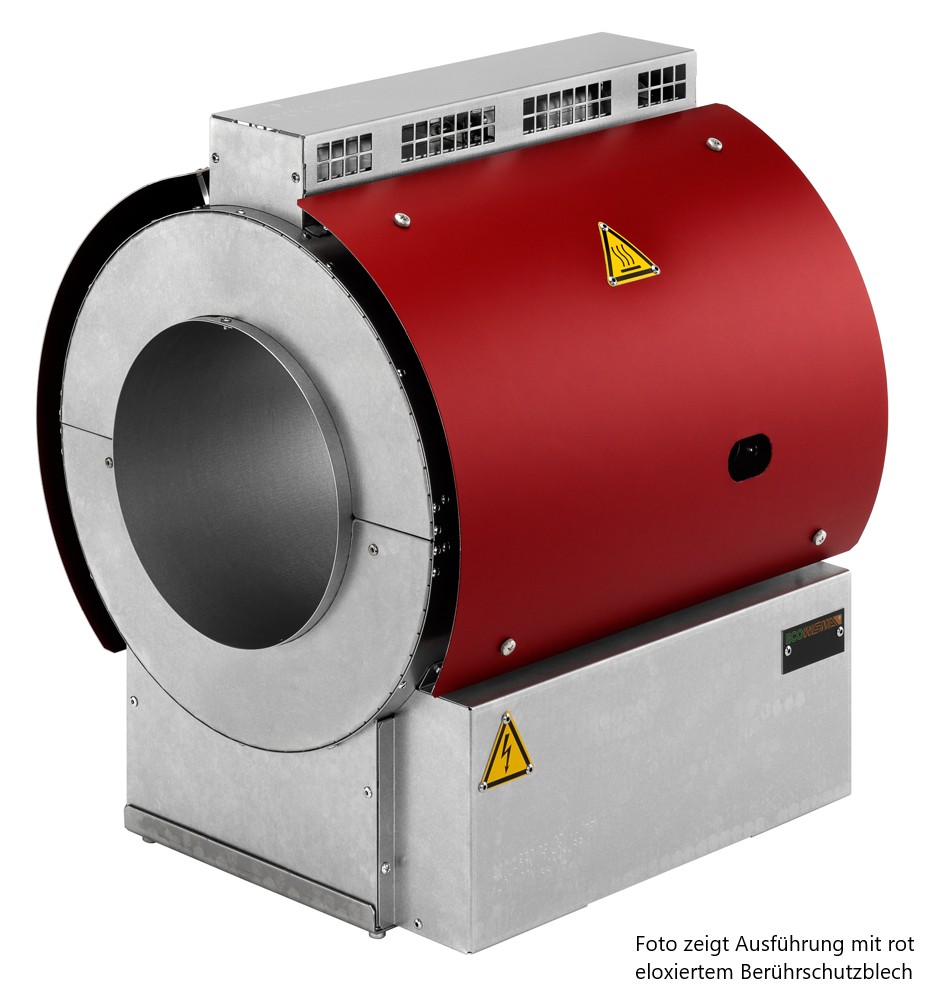

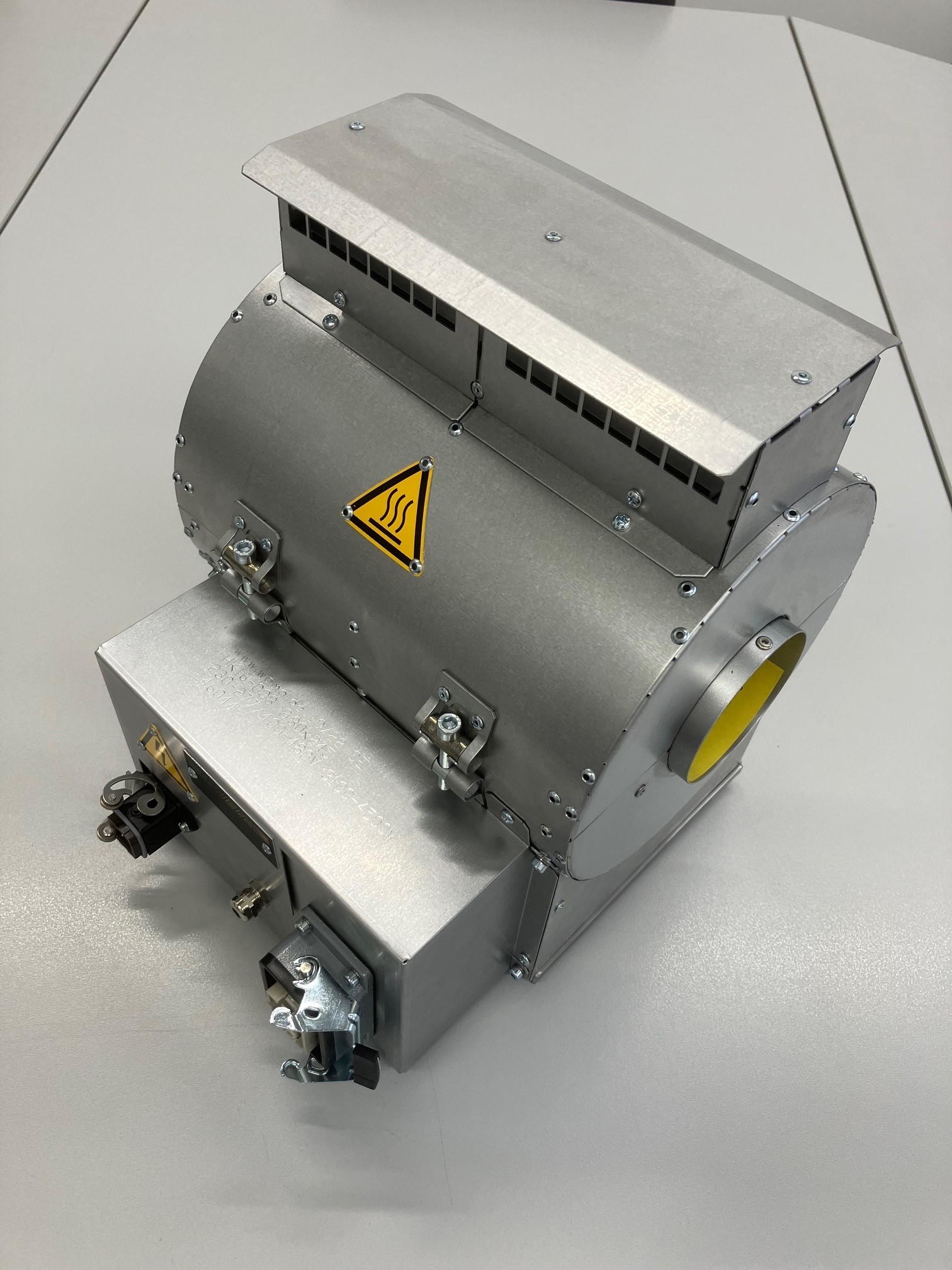

A housing casing made of 0.8 mm thick aluminised sheet steel (stainless steel on request) is subsequently fitted and encircles all the heater bands in the zone.

Additional fixing brackets are attached to the bottom part of the housing casing in order to make assembly easier and support the weight.

The efficient implemented cooling fan in addition to specially-shaped air deflectors for distribution of the cooling air in the axial and tangential directions are also integrated in the bottom half of the housing.

The individual design of these air deflectors ensures the best-possible even circumfluent flow of the cylinder, and therefore counteracts any undesirable bending of the cylinder and corresponding wear.

The spacious electrical connection chamber, which stands out due to its optimum accessibility, is located on the side of the fan housing.

The individual heating ribbon braids are connected on a ceramic terminal strip in this case.

An electrical supply cable at a defined length can be connected at the works if requested.

The size of the air outlet opening in the upper part of the housing casing is matched to the corresponding flow volume of the intended fan, and is fitted with a grille structure for optimum airflow.

Additional air deflectors can be fitted to the air outlet opening as an option.

Sensor bores and apertures will be taken into account as far as technically possible.

The completely removable housing cover, the fixing bracket on the lower shell and the spreadable ceramic heater bands ensure a high level of assembly-friendliness.

A UL / CSA-certified execution is also available.

Technical specification:

- Material housing: 0,8 mm aluminised sheet steel (stainless steel on request)

- Voltage/tie-in: in acc. w. specification

- Heating capacity: max. 7 W/cm², related to the heater bands

- Temperatur max.: 300 °C (special version to 500 °C)

- Diameter: from 80 mm

- Width: from 240 mm

- Circular plate height: 36,5 mm